CONSULTING

We advise planners and architects on implementation from the very first idea – with sketches, drawings or first plans. We would be glad to advise you – either by either by phone, e-mail and / or in person on your premises.

PLANNING

Our technical office undertakes the planning of mesh, cables and steelworks. The wishes and requirements of each client and planner are taken into account in the planning process. Our services are individually tailored to each project.

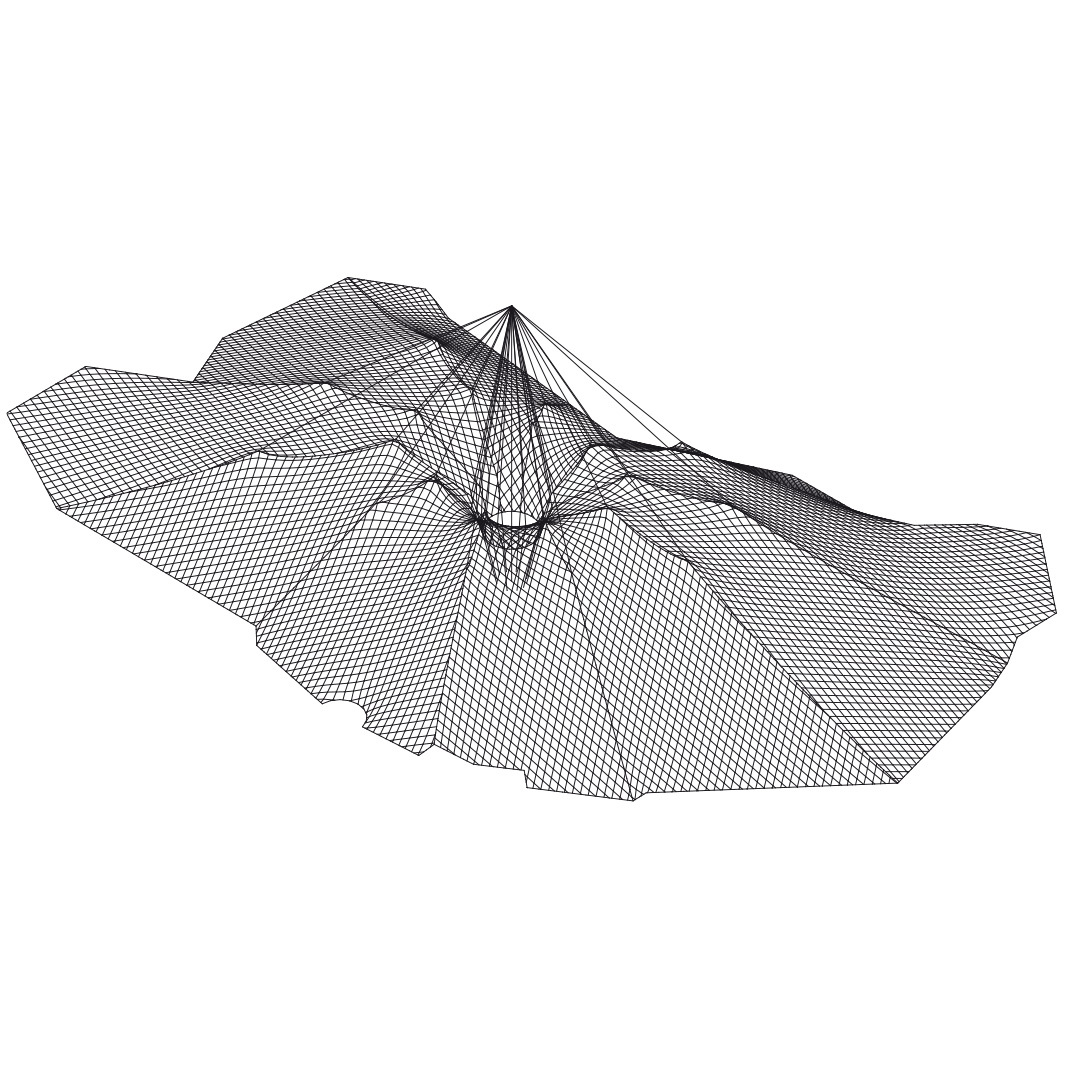

STATICAL ANALYSIS

If necessary, we also supply the structural calculations for the pretensioned systems – taking all load cases into account. The dimensioning of our stainless steel cables and mesh – as well as the adjacent steelwork components – are determined by means of computer-aided design.

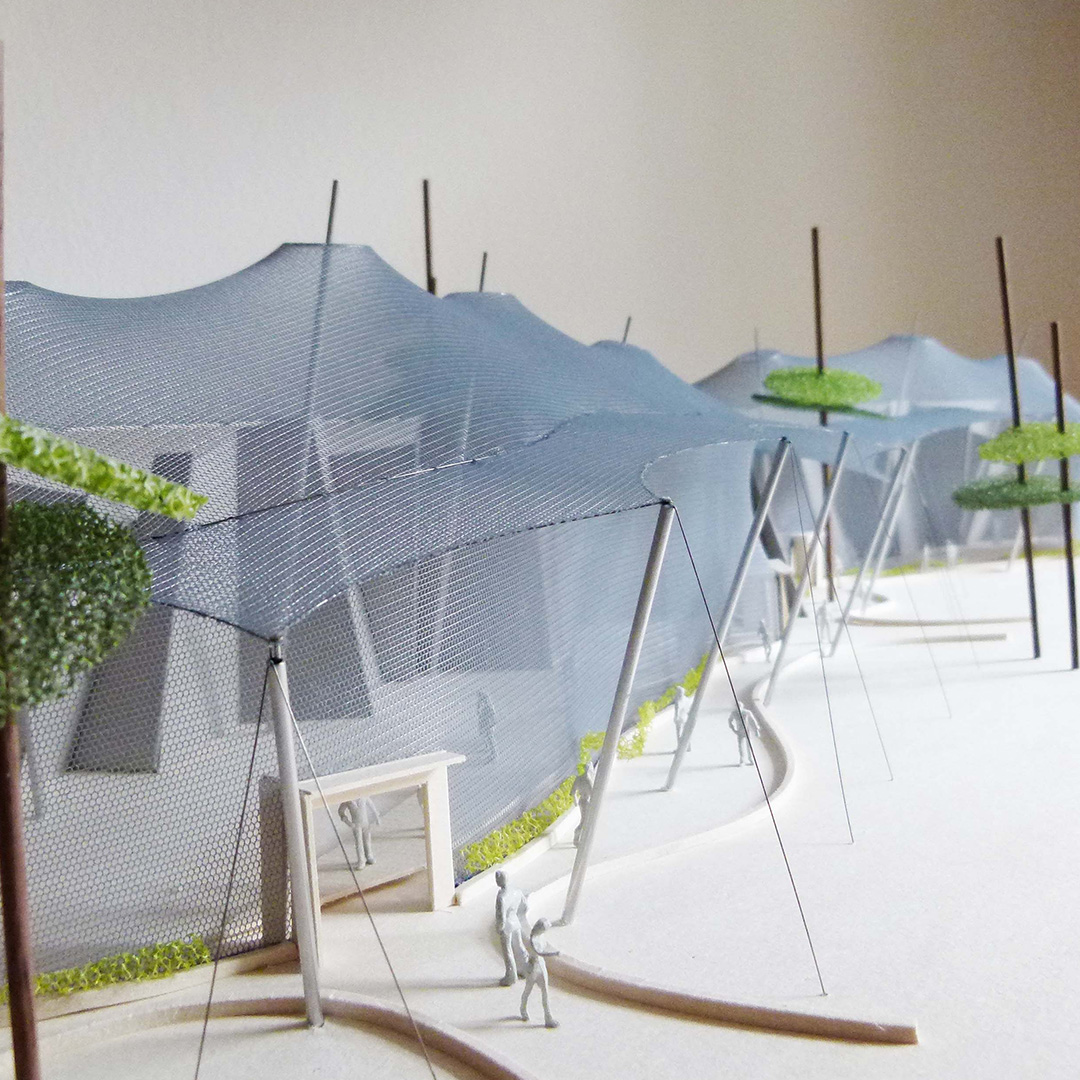

MANUFACTURING

The finished drawings of the stainless steel mesh are then taken to our production department, where they are implemented promptly and precisely. The individual mesh areas are preconfectioned precisely according to the installation concept. Stainless steel cable assemblies from 1 to 26mm in diameter are confectioned to custom-specific lenghts in our works. Our production facilities in Europe and USA compy with the highest quality standards.

INSTALLATION

The stainless steel cable and X-TEND stainless steel mesh systems are installed on site by our experienced assembly team. In addition to complete assembly, there is also the option of assembly supervision, in which technically versed fitters from the customer are instructed and accompanied. Our project managers plan, supervise and coordinate all the installation steps and make sure they are completed on time.

MAINTENANCE

With a wide range of maintenance options, we remain your reliable partner during the entire service life and thus ensure a permanent trouble-free operation.